high alumina insulation brick

Insulation refractory products refers to the products with porosity of not less than 45%. Insulation products are characterized by high porosity, small bulk density, low thermal conductivity, good insulation performance. It can preserve heat,as well as resistant heat, can be used as a insulation layer for a variety of thermal insulation equipment, and some can also be used as a working layer, is energy-saving materials to build a variety of kiln. Comparing with general dense refractory products, it is more effective to reduce the heat loss by 40% to 50%, especially for non-continuous thermal equipment.

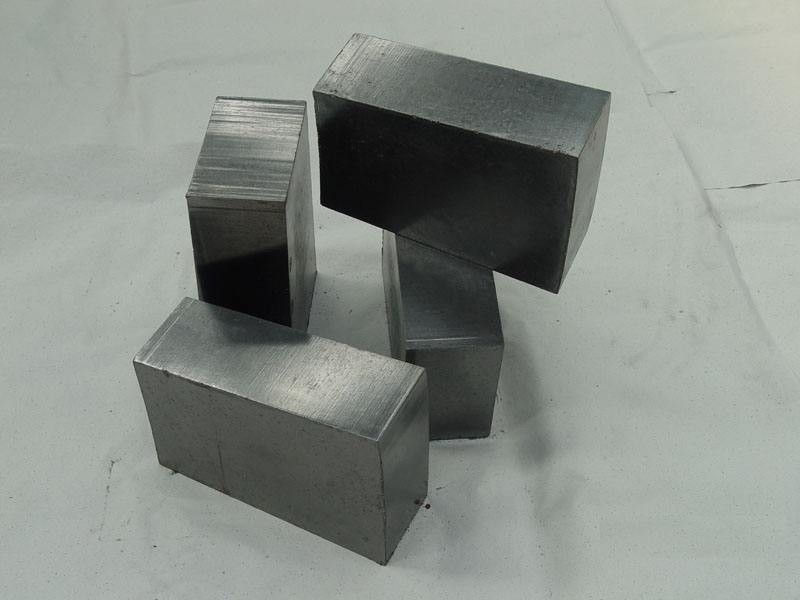

High aluminum insulation refractory brick

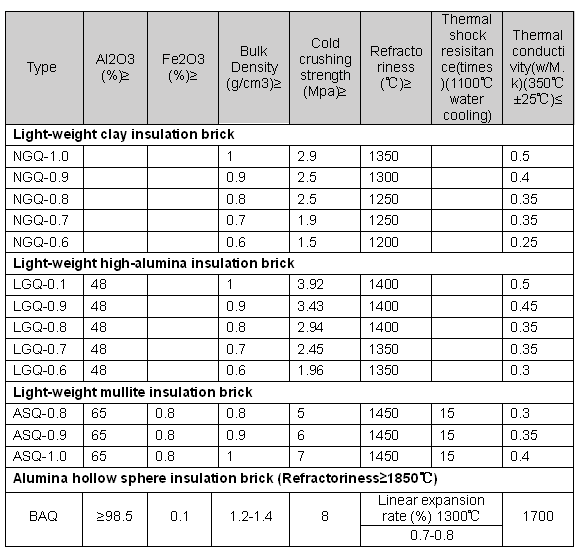

High aluminum insulation refractory bricks are made of bauxite as the main raw material with al2o3 content of not less than 48%. In order to improve the product performance , industrial alumina, corundum, sillimanite, kyanite, silica fine powder are added to get the different bulk density. The working temperature is 1250-1350 ℃, some can up to 1550 ℃.

Production Process:

High-aluminum insulation brick mostly use foam production, the product bulk density is 0.4-1.0g / cm3, can also use burnout process.

Application of high alumina brick

Note:High aluminum insulation refractory bricks can be used for masonry insulation layer and no strong high temperature melting materials erosion site. When directly contact with the flame, the surface contact temperature of high alumina insulation brick shall not be higher than 1350 ℃.

standard size:230mm*114mm*35mm

high alumina insulation refractory brick

Packaging of high alumina insualtion bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930 or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons

Shipping of high alumina insualtion bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity guaranteed, and also in accordance with the contract and customer's requirment completely.

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the inquiry with the detail, such as the quantity, the specifications and the application of the products.

2. What is the MOQ (minimum order quantity)?

100 pcs is OK.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality problems, our company will be responsible to make compensation for it based on enough evidences.