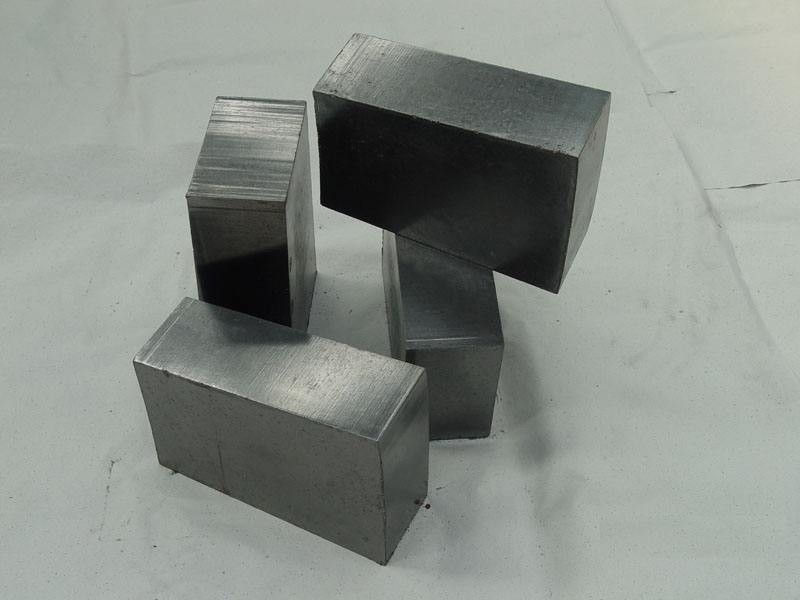

Magnesia Alumina Spinel Brick Introduction

Magnesia-Alumina Spinel Brick is in order to improve the heat stability of magnesia brick, add alumina oxide in ingredient to generate the magnesia brick which the main material is magnesia-alumina spinel.

Magnesium-alumina spinel bricks have the following advantages.

① The elastic modulus is small, magnesia alumina brick is (0.12~0.228)×105MPa, while magnesia brick is (0.6~5)×105MPa;

② MA can transfer MF from periclase and sweep FeO, and the reaction is as follows:

FeO+MgO • AI2O3→MgO+FeAl2O4

FeO+MgO→(Mg • Fe)O

MA absorbs Fe2O3 and undergoes minor expansion

③ high melting point. The melting point of spinel is 2135 ℃, and the initial melting temperature of periclase is 1995 ℃ higher. The combination of the two will improve the bonding performance of magnesia bricks.

④ The softening temperature under load is high, but the spinel formation is accompanied by volume expansion, and the ability to aggregate and recrystallize is weak, so a higher firing temperature is required.

⑤ Excellent thermal shock resistance.

⑥ High strength.

⑦ Strong corrosion resistance.

![]()

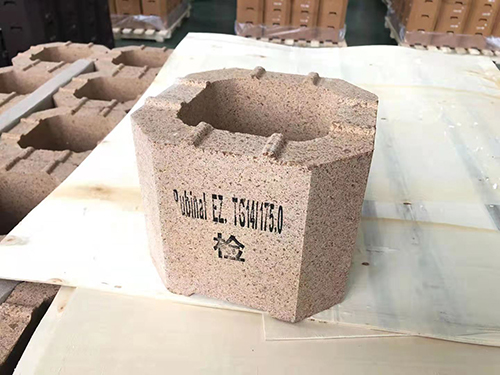

Application of Magnesia Alumina Spinel Brick

1.The magnesia-alumina spinel can be used in the cement kiln, not only avoid the chrome pollution, and has good anti-stripping performance.

2.It can be used in refractory carstables for ladles, which greatly improve the anti-erosion ability. It is widely applied to steel-making refractory material. The preparation of high quality pre-synthertic spinel provide a new material for amorphous and fixed high purity refractory.

| Items | Magnesia Alumina Spinel Brick | |||

MA-12A | MA-12B | MA-12C | MA-18 | |

MgO% | 80 | 75 | 70 | 60 |

SiO2% | 1.0 | 1.0 | 1.5 | 1.0 |

Al2O3% | 12 | 12 | 12 | 18 |

Bulk density(g/cm³) | 2.95 | 2.90 | 2.90 | 2.85 |

Apparent porosity | 18 | 18 | 18 | 18 |

Cold Crushing strength Mpa | 40 | 40 | 40 | 40 |

Refractoriness under load 0.2Mpa | 1650 | 1650 | 1650 | 1650 |

Thermal shock resistance(950℃air cool times) | 40 | 40 | 40 | 40 |

Application | Severe corrosion area | Larger than 5000mt/d kiln capacity | Economic solution | Severe corrosion area |