■ Feature

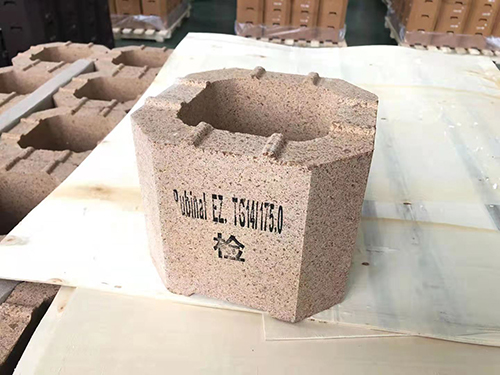

The main mineral composition of chrome corundum brick for lining and pool of the glass furnace is prun-Al2o3-cr2o3 solid solution.The secondary mineral composition is a small amount of composite spinel (or non-composite spinel), and the content of chromium oxide is 1% ~ 30% of firebrick. And in near day, high pure chrome corundum brick also make to fulfill the needs of special industries. High chromium bricks (Cr2O3≥90%) are mainly used in key parts of kilns such as coal chemical industry, chemical industry kilns, alkali-free glass fiber kilns, garbage incinerators, etc.There are two types of fused cast chrome corundum brick and sintered chrome corundum brick.

The raw material used in the chromium corundum series products is a solid solution synthesized by high-temperature melting of alumina and chromium oxide in a certain proportion. The production process of special refractory materials is used to make refractory bricks, which can improve and enhance the internal quality of the product and the high temperature performance of the product.

It has the characteristics of high refractoriness, high strength, good thermal shock stability, and strong corrosion resistance. Erosion, abrasion resistance, corrosion resistance, and structural spalling resistance have been used in metallurgy, glass, carbon black, and petrochemical industries. chromium corundum brick performance analysis

1. The refractory performance of the product can be seen from the Al2O3-Cr2O3 binary phase diagram. Al2O3 and Cr2O3 can form a continuous solid solution without eutectic. Therefore, adding Cr2O3 to the high-purity corundum material, regardless of the amount added, will not only not reduce the fire resistance of the material, but will increase the fire resistance of the material.

The refractoriness (>1790) and load softening temperature (>1700) of chrome corundum bricks are better than high-purity corundum products.

2. The strength of the product The normal temperature compressive strength of high-purity corundum bricks is generally 70-100MPa, and the normal temperature compressive strength of high-performance chromium corundum bricks is generally >150MPa, and its strength is significantly higher than that of corundum bricks. This is because during the firing process of the product, the Al2O3-Cr2O3 solid solution is formed between the particles and the particles, between the particles and the fine powder, and between the fine powder and the fine powder. The solid solution connects the particles and the fine powder like a bridge. Together, the strength of the material is greatly improved.

3. Thermal shock stability According to data, when Cr2O3 is added to corundum, when the content of Cr2O3 is 10%~66%, the thermal shock stability of the material decreases with the increase of Cr2O3 content, that is, chrome corundum bricks with low Cr2O3 content. Its thermal shock stability is better than that of chrome corundum bricks with high Cr2O3 content.

4. Slag erosion resistance  The solubility of Cr2O3 in coal gasifier slag (SiO2-CaO series) and various glass melts is much smaller than that of other oxide materials. Therefore, Cr2O3 or refractory materials containing Cr2O3 have good corrosion resistance to steel slag, non-ferrous smelting slag, coal gasification slag, oil gasification slag and various glass melts. The liquid phase viscosity of Cr2O3 melt or the reaction of Cr2O3 and slag is higher than that of other low melts, which prevents the slag from penetrating into the brick body along the capillary pores, and avoids the formation of a metamorphic layer and structural peeling.

■ Technical Data

Item | HT-GG90 | HT-GG85 | HT-GG60 | HT-GG30 | HT-GG12 |

Cr2O3 % | ≥93 | ≥86 | ≥60 | ≥30 | ≥12 |

Al2O3 % | — | — | ≤38 | ≤68 | ≤80 |

Fe2O3 % | — | — | ≤0.2 | ≤0.2 | ≤0.5 |

Apparent porosity % | ≤17 | ≤17 | ≤14 | ≤16 | ≤18 |

Bulk Density g/cm3 | ≥4.3 | ≥4.2 | ≥3.63 | ≥3.53 | ≥3.3 |

Cold compressive strength, Mpa | ≥100 | ≥100 | ≥130 | ≥130 | ≥120 |

Refractoriness under load ℃ (0.2MPa,0.6%) | ≥1680 | ≥1670 | ≥1700 | ≥1700 | ≥1700 |

Linear change rate % (1600℃×3h) | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 |