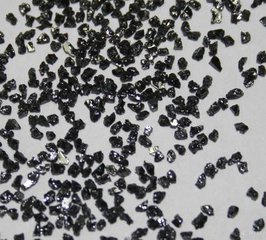

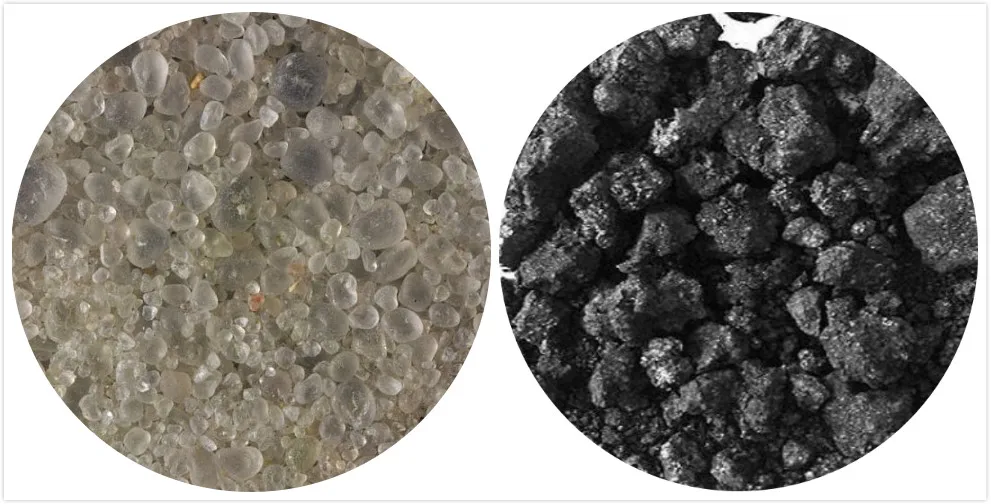

black/green silicon carbide powder

silicon carbide (SiC) powder, also known as carborundum sand, use quartz sand, petroleum coke (or coal), wood chips ( need to add salt when produce green silicon carbide), etc. as raw materials and smelt in high temperature resistance furnace. Silicon carbide in nature also has its own rare minerals, mozzanite. Silicon carbide, also known as carbon silica. In the contemporary C, N, B and other non-oxide high-tech refractory raw materials, silicon carbide for the most widely used, the most economical one, can be called gold sand or refractory sand.

Substance species:

Silicon carbide is divided into two commonly used basic varieties: black and green.

1.black silicon carbide containing about 95% SiC, its toughness is higher than green silicon carbide, mostly used for processing low tensile strength materials, such as glass, ceramics, stone, refractory materials, cast iron and nonferrous metals.

2.green silicon carbide contains about 97% SiC with good self-sharpening, and most used for processing carbide, titanium and optical glass,also for honing cylinder liner and grinding high-speed steel cutting tools.

Due to low content of natural ingredients, silicon carbide is mostly man-made. Common method mix the quartz sand and coke, utilize SiO2 and petroleum coke, add salt and wood chips, put into the electric furnace, heated to about 2000 ° C high temperature, to get silicon carbide powder after a variety of chemical processes.

Main raw material of SiC powder:

quartz sand petroleum coke

Application of silicon carbide powder:

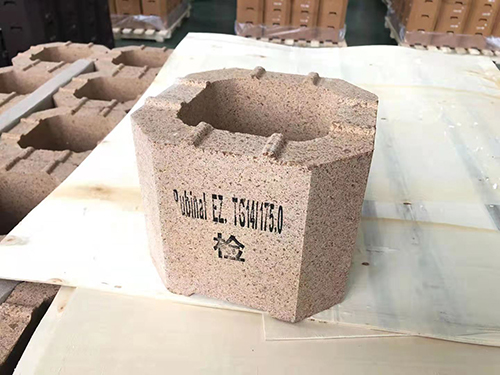

There are four main applications of silicon carbide: functional ceramics, advanced refractory materials, abrasive and metallurgical materials.

1.as abrasive, can be used to do abrasive, such as grinding wheel, Whetstone, grinding head, sand tile and so on.

2.as metallurgical deoxidizer and high temperature materials.

3.high purity single crystal, can be used to manufacture semiconductors and silicon carbide fiber.

Hongtai produced European standard Silicon carbide powder models are as follows:

F6,F8,F10,F12,F16,F20,F22,F24,F30,F36,F40,F46,F54,F60,F70,F80,F90,F100,F120,F150,F180,F220,F240.

Hongtai Refractory can also produce Non standard SiC powder, section sand.

Parts of SiC Powder index are listed below:

Item | Grit | SIC(%) | F.C(%) | Fe2O3(%) |

Green SiC powder | F80 | 99.32 | 0.18 | 0.17 |

F120 | 99.24 | 0.19 | 0.19 | |

F150 | 99.21 | 0.20 | 0.21 | |

F220 | 99.16 | 0.21 | 0.20 | |

Black SiC powder | F12-90 | 98.5 | 0.2 | 0.6 |

F100-180 | 98 | 0.3 | 0.8 | |

F220-240 | 97 | 0.3 | 1.2 |