Fiber reinforced fireproof calcium silicate board is a new type "green" building material, with the unique environmental protection feature based on the excellent moisture, fire resistant performance. It is made by using silicon powder and calcium powder as main substrate, natural wood fiber as reinforcing material, mixed with other auxiliary materials, through the flow slurry molding, to form and conserve a new type build materials in the high temperature and high pressure.

The main ingredients and formula: silica powder + calcium powder + natural wood pulp fiber

Classification of Fiber reinforced fireproof calcium silicate board:

Fiber reinforced fireproof calcium silicate board is divided into thermal insulation Fiber reinforced fireproof calcium silicate board and decorative Fiber reinforced fireproof calcium silicate board.

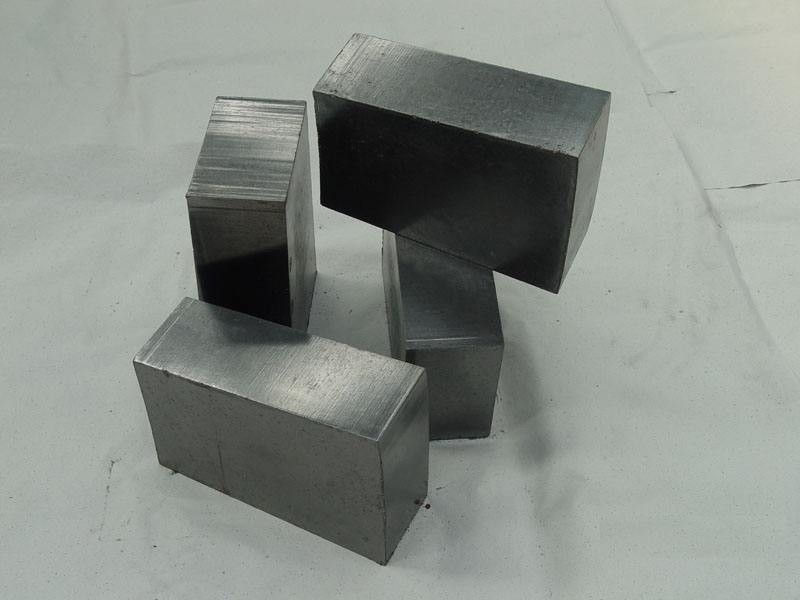

1. Fiber reinforced fireproof calcium silicate board for thermal insulation

Thermal insulation Fiber reinforced fireproof calcium silicate board is also called microporous calcium silicate, is a white, hard new insulation material, with good characteristics of light weight, high strength, small thermal conductivity, high temperature resistance, corrosion resistance, can be cut and saw and so on. Widely used in electric power, metallurgy, petrochemical, construction, ship and other areas of equipment pipelines, wall roof insulation and fire insulation. Thickness is usually above 30mm, the density is 200-1000kg / m3.

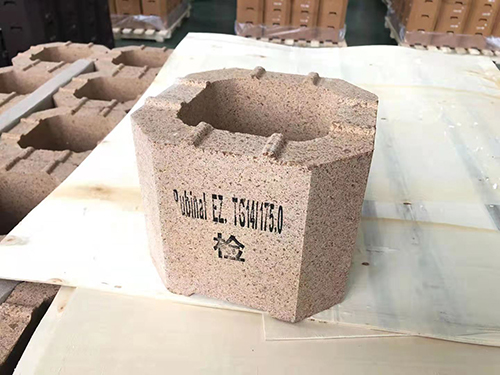

2. Decorative Fiber reinforced fireproof calcium silicate board

Decorative Fiber reinforced fireproof calcium silicate board, invented by the United States OCFG company, new type building plate which is known in the world by its comprehensive performance. Thickness is 4-20mm, length and width is 1220 * 2440mm mainly. At the same time, decorative calcium silicate ceilings processed on the basis of large size of Fiber reinforced fireproof calcium silicate board, with its fire resistance, anti-sagging, varieties type and other advantages, is widely used in the ceiling.

Use place:

Commercial buildings: business buildings, entertainment venues, shopping malls, hotels;

Industrial buildings: factories, warehouses;

Residential buildings: new residential, renovated;

public places: hospitals, theaters,station.

Main application: the wall, ceiling, floor, furniture, Road sound insulation, sound absorption barrier, ship compartment and duct and other industrial boards and suction walls, sound absorption ceiling, pouring walls, composite wall panels and other areas.

Storage and delivery Note:

1. Do not collide when loading and unloading, the bottom of the transport must be flat, after loading, should take fixed measures to ensure that does not shift and collision on the way.

2. When hoisting or forking, the pallet sheet must be stacked neatly to prevent the rope or forklift shovel from touching the edge of the board.

3. During manual loading and unloading, must pay attention to prevent debris from being caught between the plates, if not cleaned in time, may make the plate fractured or deformed.

4. When handling boards, they should be erected on both sides of double hand plate.

5. The plate should be stacked on a flat surface or placed with a special wooden pallet at the bottom, a small amount of boards can not stand upright.

6. The plate should be stored in the indoor warehouse. if the open storage, the boards should be covered with the sheet.

Specifications of Fiber reinforced fireproof calcium silicate board

| Item | specifications | |||

| D0.8 | D1.0 | D1.3 | ||

| B.D.(g/cm3;) | 0.75<D0.90 | 0.90<D1.20 | 1.20<D1.40 | |

| M.O.R. MPa | e=5,6,8 | 8 | 9 | 12 |

| e=10,12,15 | 6 | 7 | 9 | |

| e 20 | 5 | 6 | 8 | |

| Thermal conductivity [W/(m K)] | 0.25 | 0.29 | 0.30 | |

| Moisture content % | 10 | |||

| Wet swell rate % | 0.25 | |||