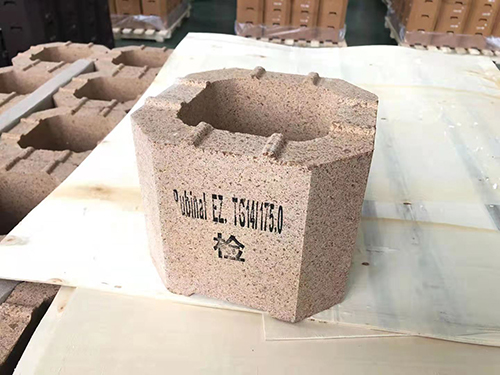

Tundish nozzle is an important component of continuous casting. Through the tundish nozzle, the molten steel flows from the tundish into the crystallizer. During this process, the outlet aperture will be eroded and widened, the amount of molten steel per unit of time increases and the surface of molten steel in the crystallizer rises, which requires increasing casting speed to digest the excess molten steel. With the further erode and widen of outlet aperture, adjusting casting speed can not digest all the excess molten steel, then releasing the excess molten steel through the mouth of the emergency is adopted though it's a waste of steel enterprises. Therefore, whether the outlet aperture of tundish nozzle remains constant is a most important measure of the quality. Usually, it is measured through the total use time in actual production.

Advantage

1. Lower-consumption on refractory material.

2. Simple-structure, light on weight.

3. Reliable on working performance.

4. Improve the working efficiency.

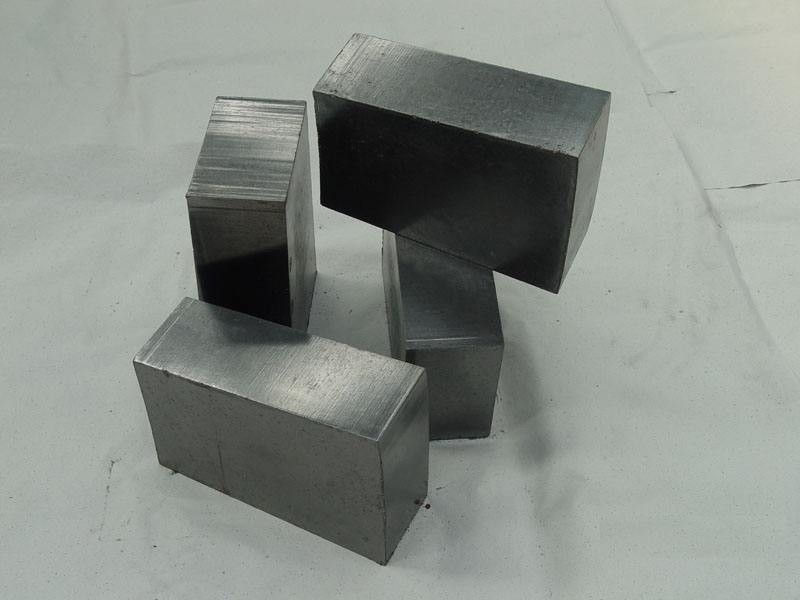

Ladle nozzle

Model no. | SSK-1 | SSK-2 | XSK-1 | XSK-2 |

Al2O3 | 75 | 80 | 75 | 80 |

C | 6 | 6 | 6 | 6 |

Refractoriness /C, | 1790 | 1790 | 1790 | 1790 |

Bulk density g/cm3, | 2.70 | 2.90 | 2.70 | 2.90 |

Apparent porosity /%,≤ | 9 | 9 | 9 | 9 |

Crushing strength /MPa, | 50 | 50 | 50 | 50 |

Tundish nozzle

tem | Index | ||

Zirconium core | Coat | ||

XF-94Z | XF-95Z | WG-65 | |

ZrO2 | 94 | 95 | - |

Al2O3 + C | 0 | 0 | 65 |

Apparent porosity % ≤ | 8 | 7 | 12 |

Bulk density g/cm3 | 4.5 | 5.4 | 2.8 |